FiberCore Europe's Norwegian partner, Module Solutions & Systems, together with Multiconsult, will design and deliver innovative and sustainable bridge maintenance solutions to the municipality of Vestland County, in Norway.

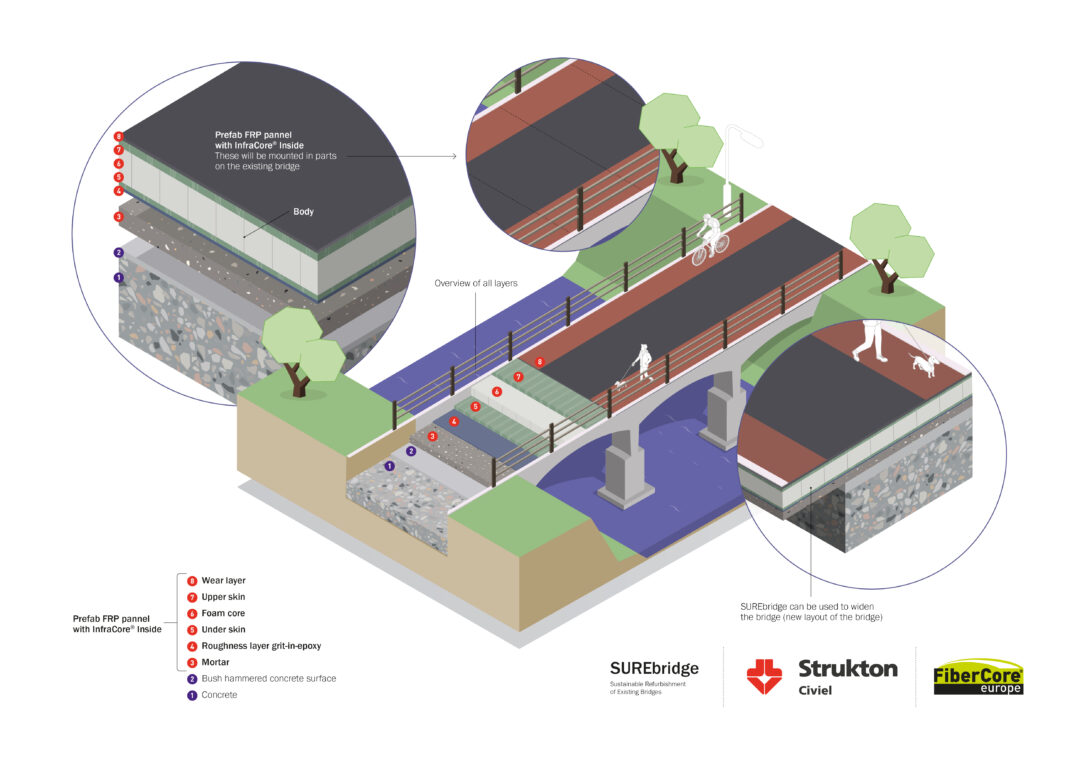

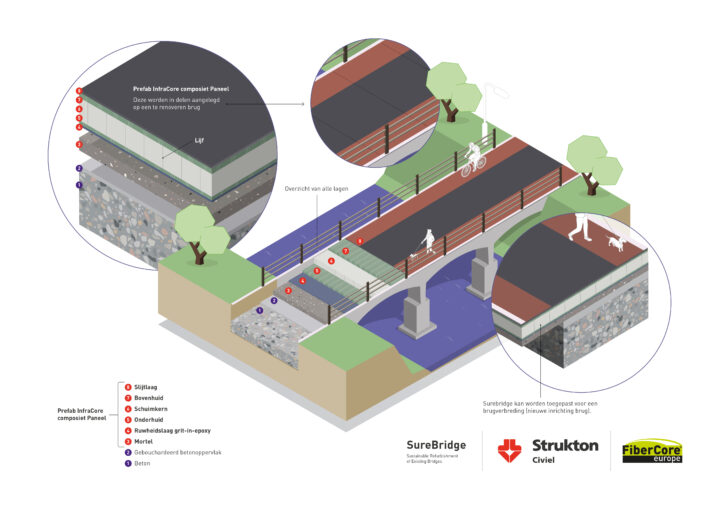

Two concepts are being designed, one of which, SUREbridge with InfraCore®Inside, reinforces the existing concrete deck with a thin composite deck on two bridges. The second concept replaces the existing concrete bridge deck with a composite deck on two steel girder bridges. Both solutions focus on increased safety, longer service life, reduced installation time, reduced maintenance costs and, last but not least, increased reuse of existing bridges.

More gone for the money.

This innovation project aims to test whether replacing concrete with composite can reduce maintenance costs. Composite material has not yet been tested in an environment provided by Norwegian roads, but the material's properties give good reason to believe it will work.

Today's solution with the use of concrete clinkers appears to require more maintenance, due to chloride intrusion and frost damage that can lead to corrosion on reinforcement and concrete damage. Using composite will eliminate this problem.

The project also aims to reduce greenhouse gas emissions, as "keeping existing bridges alive longer" can be achieved by delaying the replacement of old bridges with new ones. This will directly contribute to the national goals of better value for money and reduced greenhouse gas emissions.

Image shows how the SUREbridge concept with InfraCore®Inside is layered.

Increased road safety

The project includes design, production and installation of four bridges in Vestland County. The new composite decks will be able to strengthen the bridges so that both the superstructure can be secured against water and salt and a new asphalt wearing course can be applied. In addition, it will be possible to install approved bridge railings which will lead to a great improvement in road safety at the bridges in question.

Virtually maintenance free

The composite material used for the bridge decks is a polymer matrix reinforced with fiberglass, often called FRP (Fiber Reinforced Polymer). The material is virtually maintenance-free and will be able to significantly extend the life of aging bridges. The concepts also allow for reduced road closure time in some cases during the construction period. This is very beneficial because many county roads are narrow and have no detour options.

Supported by Innovation Norway, the innovation project will ensure that these new concepts are designed based on Norwegian regulations and manuals, and tested at full scale under Norwegian climatic conditions.

About MSS

Module Solutions & Systems AS ("MSS") is an innovative provider of composite bridge solutions, "nano-based deep stabilization technology" and "sheet piling solutions" in alternative material choices. The solutions are modern and future-oriented, adapted to a constantly changing infrastructure sector with an increased focus on the environment. Our focus is to provide the market with the most innovative products, environmentally oriented and always with the safety aspect as the first priority. This results in providing our customers with the best possible LCA and LCC for their projects.