General technical description

The SUREbridge method is an innovative concept in which the structural capacity of the bridge is increased. This is done by connecting a lightweight composite panel to the existing bridge by means of mortar. This can possibly be combined with (prestressed) carbon reinforcement on the underside of the bridge. These measures will strengthen both the compression zone and the tensile zone. It is true that the structural height increases slightly, but this increases the bearing capacity of the bridge almost by a factor of 2. The bridge can also be widened to a small extent, for example for a pedestrian or bicycle path.

Demolition of the existing structure is not necessary (sustainable) and the execution time of this method is short (minimal disruption). The reinforced structure can last another 30 to 50 years and meets today's load requirements.

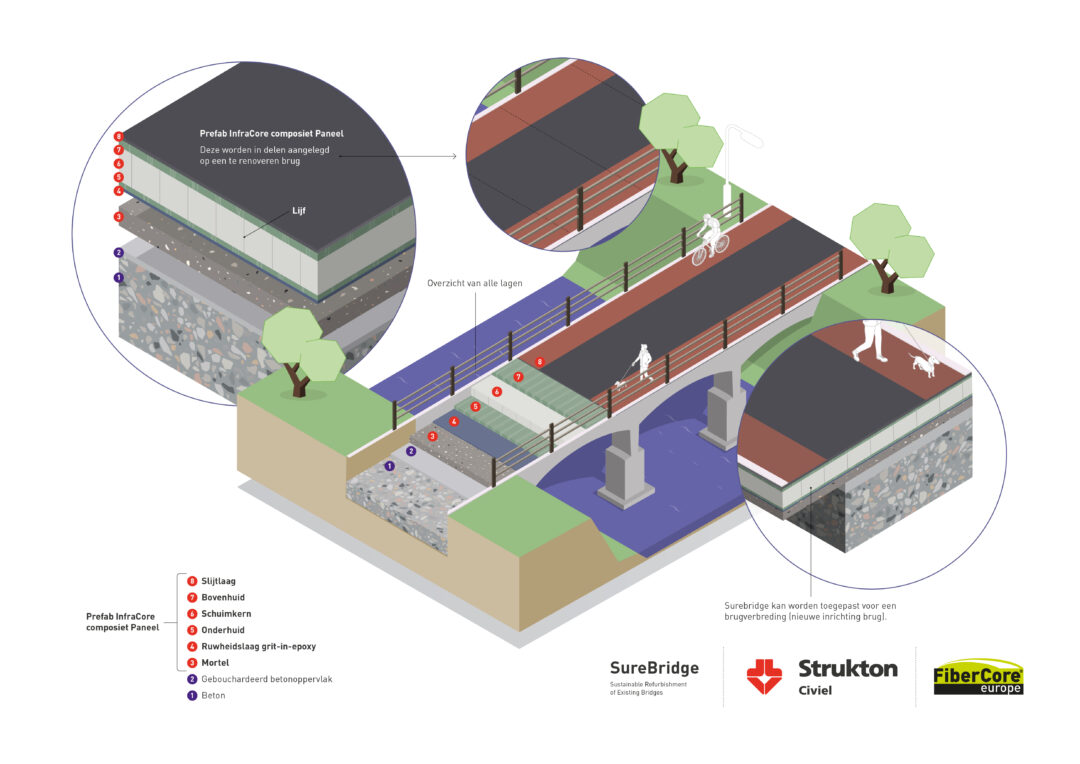

The figure below provides an overview of the SUREbridge system:

Installation.

To install the SUREbridge system, the existing asphalt is first removed until the top of the existing concrete bridge is exposed. Respecting a gap, the composite deck is then placed on studs. This deck has a rough layer on the underside for the purpose of shear adhesion with the mortar. Finally, the gap is injected with mortar. This is so fluid, strong and low-shrink that it fills the gap completely.

In cases where the existing bridge has a layer of asphalt, removing it saves construction height and deadweight.

The cross-section of the composite overlaid bridge is shown below.

A new - fast, lightweight - way of overlaying

The overlaying of bridges is an already existing and frequently used technique in the Netherlands. However, this always involved overlays with concrete. Constructively it works similarly to the SUREbridge system, but with differences:

- An overlay with composite is much lighter than with concrete. In fact, when the existing asphalt layer is removed, the system is virtually weight neutral. No additional reinforcement is then needed, therefore, to carry the reinforcement itself;

- In SUREbridge, the top of the overlay is formed by the composite panel. This protects the underlying concrete from (further) penetration of de-icing salts;

- Because the SUREbridge system is partially prefabricated, it is faster to install;

- The SUREbridge composite panel can also be used in case of support point moments (i.e., with the tensile zone at the top of the bridge instead of at the bottom) in the tensile zone.

Calculation tool

Because every bridge is different and the composite panel for the overlay is also customized, a calculation tool has been developed. In it, the properties of the existing bridge can be entered, as well as those of the composite overlay whether or not in combination with the carbon reinforcement on the underside. This allows structural engineers to quickly and easily determine the structural reinforcement to be achieved with SUREbridge. This calculation tool has been validated with 1-to-1 tests.

1-on-1 testing

SUREbridge as an innovation project has been completed and has been tested and validated in several 1-on-1 tests. Numerous implementation tests have also been conducted in consortium and in close cooperation with Windesheim Zwolle University of Applied Sciences.

These implementation tests matched the real-world situation in terms of size, conditions, material and equipment. These tests demonstrated the feasibility of the system. Moreover, the system was found not to be directly vulnerable to implementation errors - the concept as a whole is very robust. It is now ready for further development into a technology applicable to all. Work is currently underway on the first application of SUREbridge in the Netherlands on the "Toeslagweg Hardenberg" project.

Environmental gain

A major advantage of applying SUREbridge when renovating a bridge lies in environmental gain. Not having to demolish an existing bridge, and avoiding the construction of an entirely new bridge including foundations, already provides a significant environmental benefit. In addition, much less strain is placed on the bridge operator's financial resources because a construction with SUREbridge is significantly less expensive than building an entirely new bridge, including all ancillary items.

A composite deck also adds a lot of load-bearing capacity to an existing bridge at a relatively low environmental impact. In addition, studies have shown that it is precisely traffic that creates a large negative impact on a structure's CO2 emissions. This is avoided as much as possible with this construction method.

Less inconvenience

Social damage (e.g., inconvenience to residents due to detours) is also minimized because the implementation time of a SUREbridge project has a significantly shorter lead time. With a closure of 4 to 6 weeks, traffic disruption is minimal. The demolition and construction of a new bridge would take a much longer time.