Bridge renovation with SUREbridge

Extend the life of aging concrete bridges by 50 years. In half the time, at half the cost. Without demolition of the structure. With less disruption to the environment.

You may immediately think of demolishing and rebuilding an outdated concrete bridge that no longer meets today's requirements. This is not only an expensive solution; it also causes a lot of inconvenience (noise, congestion, traffic jams) and is harmful to the environment.

Sustainable and cost-saving

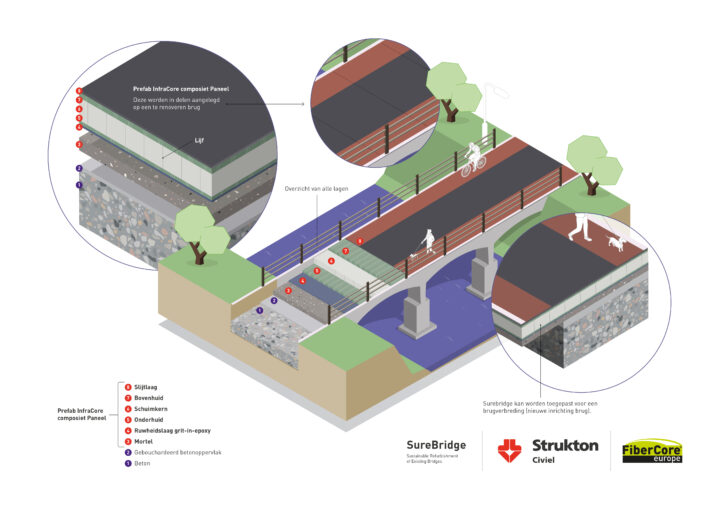

SUREbridge is the solution for fast, sustainable and cost-effective renovation of concrete bridges. The existing structure is strengthened and - if desired - widened by installing a prefabricated composite panel with InfraCore® Inside shear-resistant. The bridge thus complies with the Eurocodes and - with minimal maintenance - can last for many years again.

By applying the method, the bridge is strengthened by a factor of 2 to 2.5, in a construction time of only 6 weeks. And because the structure does not have to be demolished, this results in savings in time, inconvenience and transport; a major environmental benefit. Costs are also saved; up to 50% compared to demolition and new construction.

Developed in a European context

SUREbridge was developed - within project Infravation - in a European context and is now being applied in the Dutch market by us as a developer in a collaboration with Strukton Civiel.

SUREbridge pilot project: Hardenberg

The municipality of Hardenberg has decided to be the first client in the Netherlands (and the world) to reconstruct the existing bridge in the Toeslagweg using the innovative SUREbridge method. Read more about this world first.

The technique

The SUREbridge method is an innovative concept in which the structural capacity of the bridge is increased. This is done by connecting a lightweight composite panel to the existing bridge by means of mortar. This can possibly be combined with (prestressed) carbon reinforcement on the underside of the bridge. These measures strengthen both the compression zone and the tensile zone. It is true that the structural height increases slightly, but this increases the bearing capacity of the bridge almost by a factor of 2. The bridge can also be widened, for example for a pedestrian or bicycle path.

Demolition of the existing structure is not necessary (sustainable) and the execution time of this method is short (minimal disruption). The reinforced structure can last another 30 to 50 years and meets today's load requirements.

Provide substantiated H&R advice with calculations by the SUREbridge Software Tool

Choosing demolition or renovation? Bring your H&R advice for aging concrete bridges fully substantiated to government agencies with a design calculation for bridge renovation with SUREbridge. Aice Consulting developed the SUREbridge Software Tool that allows you as a consulting or engineering firm to calculate the feasibility of renovation with SUREbridge within your project.

Why renovate concrete bridges with SUREbridge

- Renovation without demolition of existing structure

- Up to 50% cost savings over demolition and new construction

- Construction time of only 6 weeks, so less inconvenience to the surrounding area

- More strength and stiffness, thus more load-bearing capacity

- Light in weight: saving on foundation

- Widening of road surface possible

- Lifetime extension up to 50 years

- Practically maintenance free

- No fatigue or corrosion

- Lowcarbon footprint

- Circular

Also choose nuisance-free bridge renovation

Also choose bridge renovation with SUREbridge. The result: a stronger and wider bridge at lower costs and with less inconvenience. Maintenance-friendly, durable and with a very long lifespan. Want to know more about the possibilities? Our consulting team is ready for you.